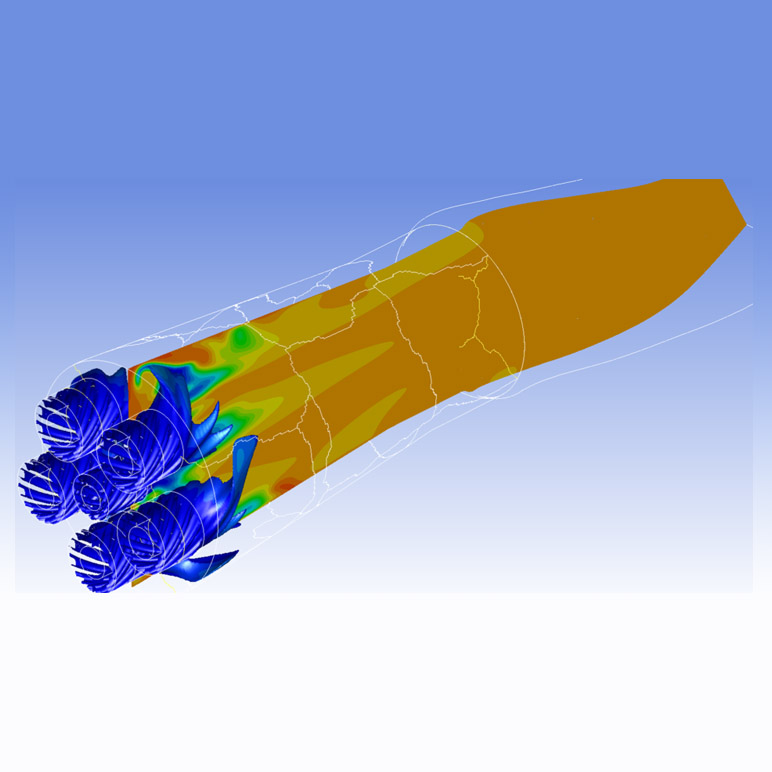

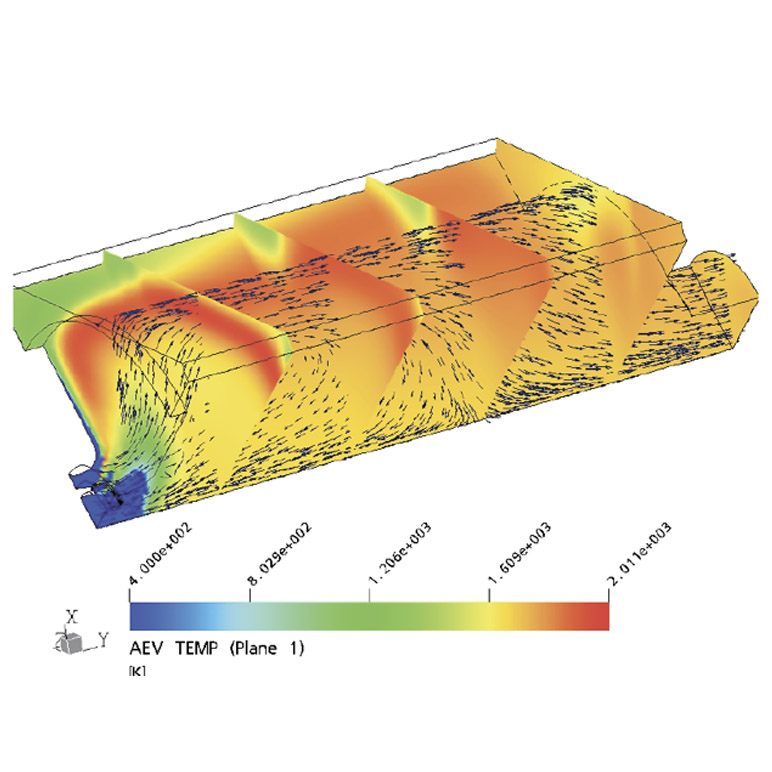

GT combustor modeling

Mateq Process has extensive experience in modeling and analyzing flow, combustion and heat transfer in gas turbine combustion chambers.

Combustion2 is een joint venture van Mateq Process en SUSCOMB.

Combustion2 levert verbrandingsapparatuur voor circulaire energiesystemen.

Contact data

+31(0)6 20 66 26 75

info@mateqprocess.com

terms of delivery

privacy (in Dutch)

cookiebeleid

©Mateq Process